Carmix mobile self loading concrete mixer

Comparison of stationary and mobile self loading concrete mixing plants

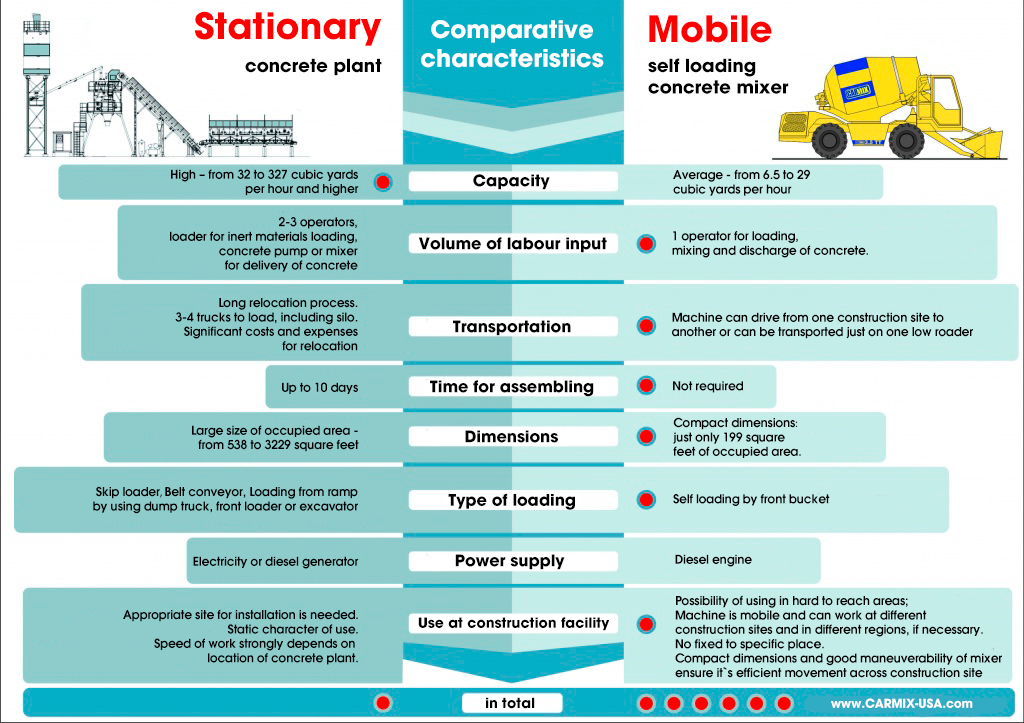

There are two types of concrete mixing plants: mobile and stationary plants. Choice of right equipment depends on tasks that you need to solve.

Stationary concrete plant due to its high level of capacity and productivity (up to 33 cubic yards/h.) ideally suits construction of large scale facilities as well as for production of ready mix concrete for sale.

It makes sense to choose stationary plant if you plan to do continuous works at one facility as it is very hard to transport such a plant. For this you will need to hire several trucks and installation / dismantling equipment can take up to 10 days. Also you will need to have appropriate site with special foundations and occupied surface area can vary from 107 square feet to 3 300 square feet.

Mostly, stationary concrete mixing plants need connection to electricity. Diesel generators can also serve as alternative source of power for some types of stationary plants. Due to long distance between construction site and stationary plant, speed of your works at construction site can significantly slow down while waiting for the mixer with concrete to come.

It is also worth mentioning that for using stationary concrete plant you will need additional special machines such as dump trucks and front loaders for loading inert materials as well as concrete mixers for transportation of concrete to construction site.

Taking into consideration expenses related to installation of conventional concrete batching plant, it is necessary to be aware that you can hardly cover large territory by such a plant in terms of delivery of concrete. Therefore, it is hardly justifiable to use stationary batching plant if you need concrete at various remote locations. Delivery of concrete till the destination place in a large city is associated with specific difficulties which lead to loosening the time, decrease of working efficiency and even spoiling of concrete solution. Necessity to deliver concrete to remote sites with limited demand in concrete, served as a trigger for appearance of self loading mobile concrete plants in the market. Self loading mobile concrete mixing plant produces sufficient volumes of concrete and these machines are easy in operation and absolutely safe. 4×4 wheel chassis ensures high off-road performance of machine. At the same time compact dimensions of self loading mixer allows it to drive on public roads. Alternative option for transportation of mixer is to use a special trailer. It is also possible to transport mixer by low roader (or by any other alternative). Therefore, expenses for transportation can be minimized.

Self loading concrete mixer does not need to be assembled in order to start production of concrete. After arrival of machine you can immediately proceed to produce and deliver concrete. All you need is to have inert materials at the site (water, sand, aggregates, different admixtures in case of need). With some organisational measures output of such self loading concrete mixer can reach anywhere from 6.5 cubic yards to 28.7 cubic yards/hour without any expenses for transportation of ready mix to the place of discharge.

Carmix concrete mixers are equipped with Perkins and Cummins diesel engines. Such compact concrete mixer has good manoeuvrability. It can easily approach place of discharge of concrete even within limited space of construction site.

The price of such plant is justified by quick payback period as you can significantly decrease cost of production of concrete by using Carmix. It is always more profitable to produce your own concrete at construction site rather than buy it from outside suppliers.

High mobility of Carmix mixer allows to move it quickly to another site and you do not need to bear additional costs and time associated with it`s dismantling and loading (as machine can get on the trailer by itself or drive to place of work on its own). In comparison with stationary concrete plant, it is enough to have just one operator who can control process of loading of components, mixing and discharge or ready mix.

Comparative infographics of mobile self loading concrete mixers and stationary concrete plants clearly demonstrates advantages of use of both types of equipment :