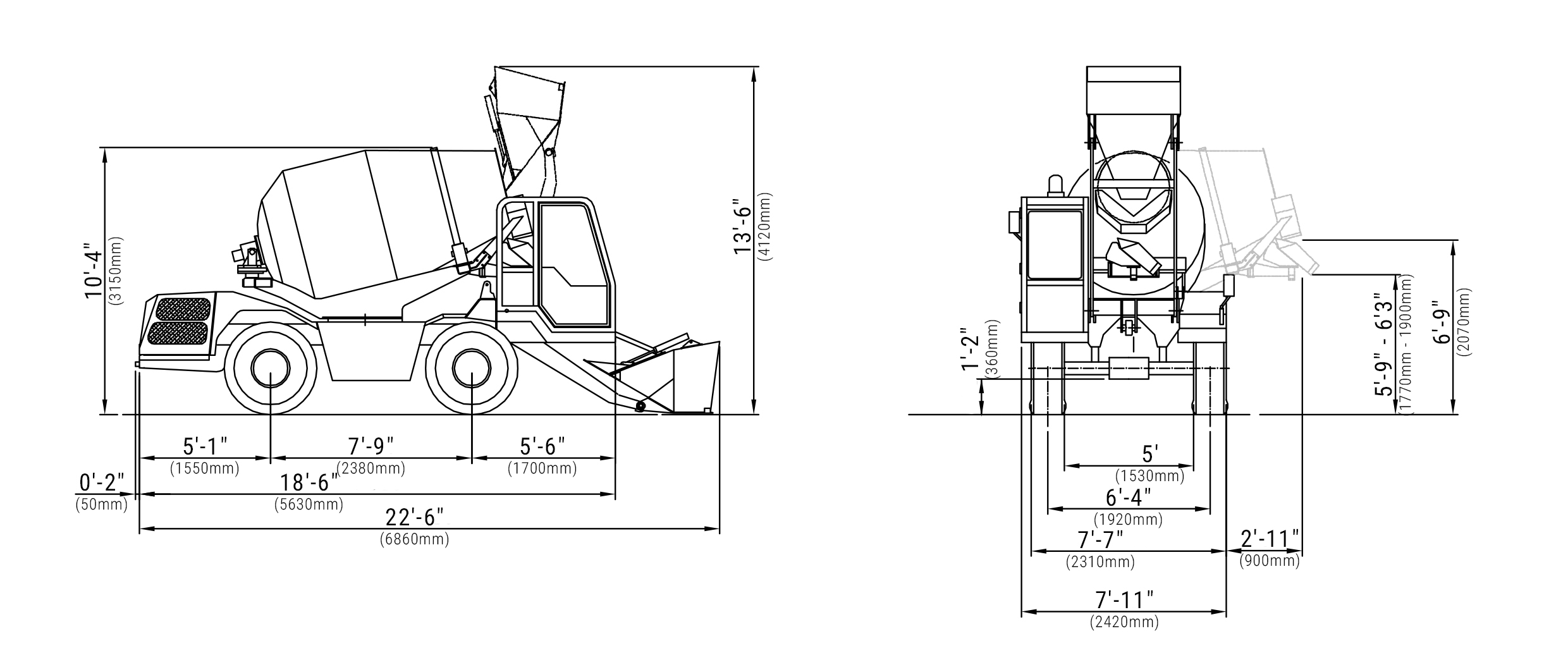

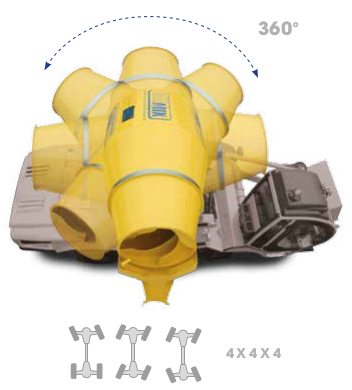

Mobile concrete plant, CARMIX 3,5 TT is designed specifically for on site production of concrete or mortar. With a lower capacity (70 yd3 per shift compared compared to 90 yd3 in the CARMIX 5.5 XL), this model is more maneuverable. Main fields of application: casting of reinforced concrete products, construction of low-rise structures. Thanks to the rotating drum, unloading of the finished mixture is carried out on 4 sides at 300º, to a height of up to 6.56 ft. The loading bucket has a capacity of 131 gal, and the exact dosage of the components is carried out thanks to the hydraulic shut off gate installed inside the bucket and the electronic, strain gauge weighing system with a computer and a printer.

Drum capacity 1.281 gal. Concrete drum output: 4.58 yd³, SLUMP S1 Class, yield not vibrated. Double mixing screws, cover for emergency unloading. Drum rotation by hydraulic motor and planetary reducers. Mixing and discharging speed indipendent from r.p.m. of diesel engine. Discharging by reversing drum. The mixing unit is slewing hydraulically through 270° for high discharge over 2 ft on the four sides of the vehicle.

Drum capacity 1.281 gal. Concrete drum output: 4.58 yd³, SLUMP S1 Class, yield not vibrated. Double mixing screws, cover for emergency unloading. Drum rotation by hydraulic motor and planetary reducers. Mixing and discharging speed indipendent from r.p.m. of diesel engine. Discharging by reversing drum. The mixing unit is slewing hydraulically through 270° for high discharge over 2 ft on the four sides of the vehicle.

Perkins 1104 D-44 TA Turbo-Diesel, watercooled, 4 cylinders. Rated power KW 83 (111 HP) set at 2.300 rpm. Engine mounted transversal on the rear.

Perkins 1104 D-44 TA Turbo-Diesel, watercooled, 4 cylinders. Rated power KW 83 (111 HP) set at 2.300 rpm. Engine mounted transversal on the rear.

Hydrostatic Bosch Rexroth. Pump and motor are connected to the differentials through a 2 speed reducer (working and transfer). 4 wheel drive and steering.

Hydrostatic Bosch Rexroth. Pump and motor are connected to the differentials through a 2 speed reducer (working and transfer). 4 wheel drive and steering.

Dana Spicer with oil bath disc brakes and planetary reducers.

Dana Spicer with oil bath disc brakes and planetary reducers.

Slewing and hydraulically tilting. Fitted with two pins easily detachable to increase the discharge height.

Slewing and hydraulically tilting. Fitted with two pins easily detachable to increase the discharge height.

Self-contained. Hydraulic driven water pump, water meter, washing outlet 400(*)min High pressure water pump.

Self-contained. Hydraulic driven water pump, water meter, washing outlet 400(*)min High pressure water pump.

Fully loaded 30%.

Fully loaded 30%.

Oil bath disc brakes inside differential axles. Twin indipendent circuits. Negative hydraulic parking brake.

Oil bath disc brakes inside differential axles. Twin indipendent circuits. Negative hydraulic parking brake.

Off road industrial type 16/70-20 PR 14

Off road industrial type 16/70-20 PR 14

Hydrostatic. 3 ways steering. Radius: internal: 3.58 ft, external 12.14 ft

Hydrostatic. 3 ways steering. Radius: internal: 3.58 ft, external 12.14 ft

Working speed from 0 to 5.6 mph, road transfer

Working speed from 0 to 5.6 mph, road transfer

from 0 to 15.5 mph. Electric servo control.

Three circuits. 2 variable outlet

Three circuits. 2 variable outlet

pumps for hydrostatic transmission and drum rotation.

2 gear pumps for services. Inlet and outlet filter. Heat

exchanger water/oil-air type.

All hydraulic functions of shovel controlled by

All hydraulic functions of shovel controlled by

a single – fully servo controlled Joystick.

Water: 2×105 gal. Diesel: 30.38 gal, (approx.

Water: 2×105 gal. Diesel: 30.38 gal, (approx.

10 hours work). Hydraulic oil: 21.5 gal.

Steel profile specially engineered for off-road

Steel profile specially engineered for off-road

operations.

About 16.315 lb. Equally distributed on both

About 16.315 lb. Equally distributed on both

axles.

Machine equipped with checking and block

Machine equipped with checking and block

valves for maximum safety of the operator. Self control

avoids drum to slew if shovel’s arm is lifted.

The machine is equipped with Use and

The machine is equipped with Use and

Manteinance and Spare Parts Manuals according to CE

regulations.

Front cab on side of loading shovel. ROPS-FOPS type complete with double closing door. Clima, air conditioning heater available upon request.

Front cab on side of loading shovel. ROPS-FOPS type complete with double closing door. Clima, air conditioning heater available upon request.

Electronic system. “Load cells” acting on the drum, display and printer in the cab. (on request)

Electronic system. “Load cells” acting on the drum, display and printer in the cab. (on request)

Effective capacity per load 158.5 gal, complete with hydraulic opening gate. 6 buckets only per batch.

Effective capacity per load 158.5 gal, complete with hydraulic opening gate. 6 buckets only per batch.

12 Volt. 120 Ah battery for electric starter and road lighting. Safety battery cut-off.

12 Volt. 120 Ah battery for electric starter and road lighting. Safety battery cut-off.

Carmix 3.5TT is a versatile, productive and multifunctional concrete mixer. It has the optimum capacity to meet the concrete demand on sites of any complexity and scale.

Special-purpose machinery produces 4.5 cubic yards of concrete mix in 1 mixing cycle. Carmix can produce up to 4 cycles per hour if all factors affecting cycle times have been taken into account.

The mobile batching plant can withstand all kinds of weather. This model has proven its worth in cold northern regions with a short construction season. The steel housing, additional water tanks and quality components made according to European standards withstand operation in freezing temperatures down to -4 F.

Carmix 3.5TT is also able to overcome all road obstacles on construction sites: off-road, potholes, mud, snow, mountain slopes, thanks to its driving characteristics. It reaches speeds of up to 18 mph and travels up to 30 miles on its own without a trailer.

WHAT MAKES CARMIX THE BEST OFF-ROAD MOBILE BATCHING PLANT?

ACCESSORIES ON DEMAND

PROMIX: In-drum probe, easy allows to analyze your concrete: slump, volume,

temperature, humidity and ready-mix indicator: Your on site Lab!

Additive Plant

Clima (air conditioning plus heater)

Air Conditioned

Heater

Spare wheel

Additional discharging chute (cm 100)