Concrete flatwork with Carmix

Concrete flatwork refers to any type of concrete surface that is level or nearly level, such as floors, patios, sidewalks, driveways, and other horizontal surfaces. It typically involves pouring, smoothing, and finishing concrete to create a smooth, level surface. It is also called concrete slab. It’s a critical aspect of construction, as it forms the foundation for many buildings and structures.

The stages of concrete flatwork typically include:

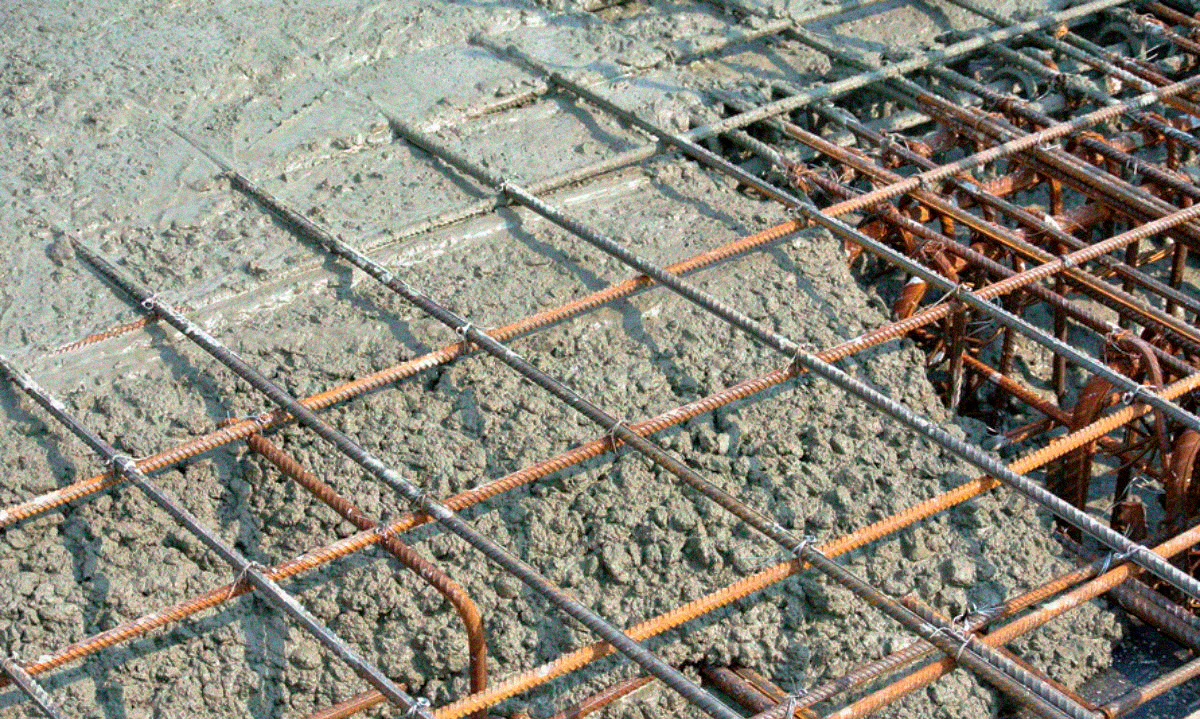

Preparation: This includes site preparation, such as excavating and grading the area, as well as laying out forms and reinforcing steel.

Pouring: This involves mixing and pouring the concrete into the forms. The concrete is typically poured in layers, called “lifts”, to ensure a smooth surface.

Finishing: After the concrete has been poured, it needs to be leveled and smoothed out to create a flat surface. This can be done with a variety of tools, such as trowels, floats, and power screeds.

Curing: The concrete needs time to set and harden before it can be used. This process is called curing and it can take several days to a week or more, depending on the weather and the mix design.

Jointing and Saw cutting: After the curing period, concrete will be jointed and saw-cut to control cracking.

Cleaning and Sealing: Once the concrete has fully cured, it will be cleaned and sealed to protect it from moisture and stains.

Note that these steps may vary depending on the specific project and the type of concrete being used.

There are several different types of concrete flatwork structures, including:

Slabs: These are the most common type of concrete flatwork and are typically used for floors, driveways, and patios. They can be either on-grade (at ground level) or suspended (elevated above the ground level)

Sidewalks: These are used for pedestrian walkways and can be found in many different settings, such as commercial and residential areas.

Curbs and Gutters: These are used to separate roadways from sidewalks and other landscaped areas. They are typically used in road and street construction.

Retaining walls: Retaining walls are used to hold back soil and prevent erosion. They can be constructed from a variety of materials, including concrete.

Stairs: Concrete stairs are used in many different settings, such as commercial buildings, homes and public areas.

Prefabricated concrete: It’s an industrialized production of concrete flatwork structures, examples are precast concrete stairs, precast retaining walls, precast curbs, etc.

Decorative Concrete: This type of concrete flatwork includes stamped, colored, and/or stenciled concrete surfaces, often used to enhance the aesthetic appeal of a surface.

Self loading mobile concrete mixers are widely used in pouring all of the above stated types of flatwork structures.

There are many factors that have to be considered before starting any project involving flatwork and Carmix can help with a number of these factors!

Site preparation: The site must be properly prepared to ensure a stable foundation for the concrete. This includes excavating and grading the area, as well as ensuring proper drainage.

Concrete mix design: The right mix design is crucial for the final strength and durability of the concrete. This includes choosing the right type of aggregate, cement, and water-to-cement ratio.

Reinforcing steel: Reinforcing steel, also known as “rebar”, is used to increase the strength of the concrete and prevent cracking. The size, spacing and placement of the rebar is crucial to ensure the durability of the structure.

Formwork: The forms used to shape the concrete must be properly built and placed to ensure a smooth and level surface.

Curing: Proper curing is essential to ensure the concrete reaches its full strength and durability.

Jointing and Saw cutting: Proper jointing and saw cutting is important to control cracking.

Quality control: The construction process must be monitored to ensure the concrete is poured, finished, and cured correctly. This includes regular testing of the concrete’s strength, slump and temperature.

Safety: Safety is crucial in any construction project, and it’s important to ensure that all workers are properly trained and that proper safety precautions are taken throughout the project.

Scheduling: It’s important to plan and schedule the project in a way that minimizes disruptions and delays, while ensuring that the project is completed on time and within budget.

A self-loading mobile concrete mixer can be used for a variety of flatwork construction projects, such as:

Pouring and finishing large concrete slabs: The self-loading mobile mixer can be used to mix and transport large quantities of concrete to the site, allowing for efficient and rapid pouring and finishing of large concrete slabs, such as floors, driveways, and patios.

Sidewalk and curb construction: The mixer can be used to mix and transport concrete for sidewalk and curb construction, allowing for quick and efficient placement of concrete in these areas.

Retaining wall construction: The mixer can be used to mix and transport concrete for retaining wall construction, allowing for quick and efficient placement of the concrete in these areas.

Repair and maintenance work: can be used to mix and transport concrete for repair and maintenance work, such as patching and resurfacing existing concrete surfaces.

Remote location works: Self-loading mobile mixer is especially useful in remote areas, where regular concrete batching plants are not available and delivery of fresh concrete is difficult.

The self-loading mobile concrete mixer can significantly increase the speed and efficiency of flatwork construction projects, by allowing for quick and easy mixing and transportation of the concrete. This can save time and money, while also improving the quality of the finished product.