How to calculate amount and cost of concrete for your project?

Table of contents (TOC):

- How to choose the right grade of concrete for your project?

- How much concrete do you need for your project?

- How to calculate cost of concrete needed

- concrete from external supplier

- concrete produced at the jobsite with Carmix

Choosing the right grade of concrete

Determine the intended use of the concrete: The first step in choosing the right grade of concrete is to understand the intended use of the concrete. For example, a slab for a residential home will have different requirements than a concrete slab for a commercial building.

Assess the load-bearing capacity: The load-bearing capacity of the concrete is an important factor to consider. The grade of concrete needed will depend on the weight and load that will be placed on the concrete.

Consider the weather conditions: The weather conditions in your area will also play a role in determining the right grade of concrete. Concrete that will be exposed to freeze-thaw cycles or high humidity will require a different grade of concrete than concrete that will be used in a dry climate.

Review the project specifications: Review the project specifications to ensure that the right grade of concrete is being used. The specifications will outline the requirements for the concrete, including the strength, durability, and other important characteristics.

Consult with a professional: If you are unsure about the right grade of concrete for your project, it is best to consult with a professional. They will be able to provide guidance on the best type of concrete for your specific project.

How much concrete will I need?

To calculate the concrete needs for a construction project, you’ll need to determine the volume of concrete required for the project and then multiply that by the density of the concrete to find the weight.

Here are the steps to calculate the concrete needs:

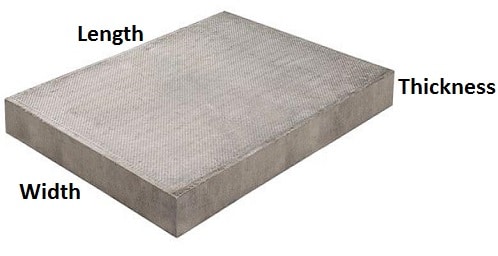

- Measure the length, width, and depth of the area where the concrete will be poured.

- Multiply the length, width, and depth together to find the volume of the area in cubic yards or cubic meters.

- Determine the thickness of the slab or the depth of the pour.

- Multiply the volume by the thickness or depth to find the total volume of concrete needed.

- Multiply the total volume by the density of the concrete (usually around 150 lbs/ft³ or 2,400 kg/m³) to find the total weight of concrete required.

It’s important to note that this calculation is an approximation and actual concrete usage may vary depending on various factors such as the type of project, the specific location and weather, and the type and brand of concrete used.

There are several allowances that are typically considered when calculating the amount of concrete needed for a project. These include:

Waste allowance – this accounts for any concrete that may be wasted during the mixing, pouring, and finishing process. A typical waste allowance is around 5-10%.

Over-excavation allowance – this accounts for any additional excavation that may be required to ensure the foundation is level and stable.

Shrinkage allowance – this accounts for the natural shrinkage of concrete as it dries and hardens.

Weather allowance – this accounts for any weather-related issues that may affect the curing and hardening of the concrete, such as extreme heat or cold.

Reinforcement allowance – this accounts for any additional concrete needed to accommodate reinforcement materials, such as steel rebar or mesh.

It’s important to note that the allowances will vary depending on the specific project and site conditions. It’s always best to consult with a professional to ensure that the right amount of concrete is ordered for the project.

How to calculate the cost of concrete?

Determine the volume of concrete needed: The volume of concrete is determined by multiplying the length, width, and depth of the area that needs to be filled with concrete. For example, if the area is 10 feet long, 10 feet wide, and 4 inches deep, the volume would be 10 x 10 x 0.33 = 33 cubic feet.

Calculate the cost of materials: The cost of materials will vary depending on the type of concrete used and the location. To calculate the cost, multiply the volume of concrete needed by the cost of the materials per cubic foot. For example, if the cost of materials is $100 per cubic foot, the cost of materials for the 33 cubic feet of concrete would be $100 x 33 = $3,300.

Factor in labor costs: The cost of labor will also vary depending on the location and the complexity of the project. To calculate the labor cost, estimate the number of hours it will take to complete the project and multiply that by the hourly labor rate. For example, if the labor rate is $50 per hour and it takes 20 hours to complete the project, the labor cost would be $50 x 20 = $1,000.

Add up the costs: To calculate the total cost of the concrete project, add up the cost of materials, labor, and any other associated costs such as equipment rental or permits. In the example above, the total cost would be $3,300 (materials) + $1,000 (labor) = $4,300.

Note: These calculations are approximate and may vary depending on the specific details of the project. It is always best to consult with a professional to get an accurate estimate.

Apart from direct concrete cost, there are a number of extra expenses that may arise when ordering concrete from a batching plant:

Delivery fee: If the concrete batching plant is located far from the construction site, they may charge a fee for delivery of the concrete.

Fuel surcharge: Some plants may charge an additional fee for fuel costs associated with operating the plant and delivering the concrete.

Concrete additives: If you require specific additives such as color pigments, fibers, or waterproofing agents, the plant may charge extra for these materials.

Pumping fee: If the plant is unable to deliver the concrete via truck, they may charge a fee for pumping the concrete to the site.

Overtime fee: If you require concrete to be delivered outside of regular business hours, the plant may charge an overtime fee for the additional labor costs.

Taxes: Some plants may charge taxes on the concrete and any additional charges.

Environmental fee: Some plants may charge a fee for properly disposing of any waste materials or for adhering to specific environmental regulations.

Additional unloading time: when concrete is delivered the plant will give a standard amount of time for the mixer to unload all the concrete. If you need more time due specific site conditions or technological aspects of the pour, you will be charged an additional hourly rate.

To calculate the concrete cost produced by Carmix you will need to:

Determine the cost of the raw materials: This includes the cost of cement, aggregate (such as sand and gravel), and water.

Calculate the cost of labor: This includes the cost of the operator and any other labor required to assist the Carmix machine.

Determine the cost of fuel and maintenance: This includes the cost of diesel used to power the Carmix machine and any maintenance or repairs that are required.

Add up all of the costs: Add up the cost of the raw materials, labor, fuel, and maintenance to get the total cost of producing the concrete.

Divide the total cost by the amount of concrete produced: To get the cost per cubic meter or yard of concrete, divide the total cost by the amount of concrete produced.

Add in any additional costs: If there are any additional costs, such as transportation or disposal, add them to the total cost.

Note: The cost may vary depending on the location, type of mix design, and other factors. It is best to consult with a professional or the manufacturer for a more accurate estimate.

To summarize, it can be seen that using Carmix as a concrete production and supply equipment has only direct costs associated with production and does not include any delivery, discharge or other fees that the batching plant may charge the end customer. Another important point is – you get the concrete free of any profit margins of the batching plant. As cost of concrete is usually one of the biggest expenses of the project, saving even 20% of the concrete costs will increase profitability of any project dramatically!

Call us and see how you can save with Carmix 4×4 self loading concrete mixer!